Over the past years Delfin has cooperated with Samsung Heavy Industries and Black&Veatch for the development of Newbuild FLNG designs.

The parties successfully completed a FEED study and subsequent post-FEED optimization work. In parallel the partners have been developing a Term Sheet for a Lump-Sum, Turnkey Engineering, Procurement, Construction, Integration and Commissioning contract (“LSTK EPCIC”) for the construction and completion of the Newbuild FLNG Vessel, which is being completed into a full Contract in early 2023.

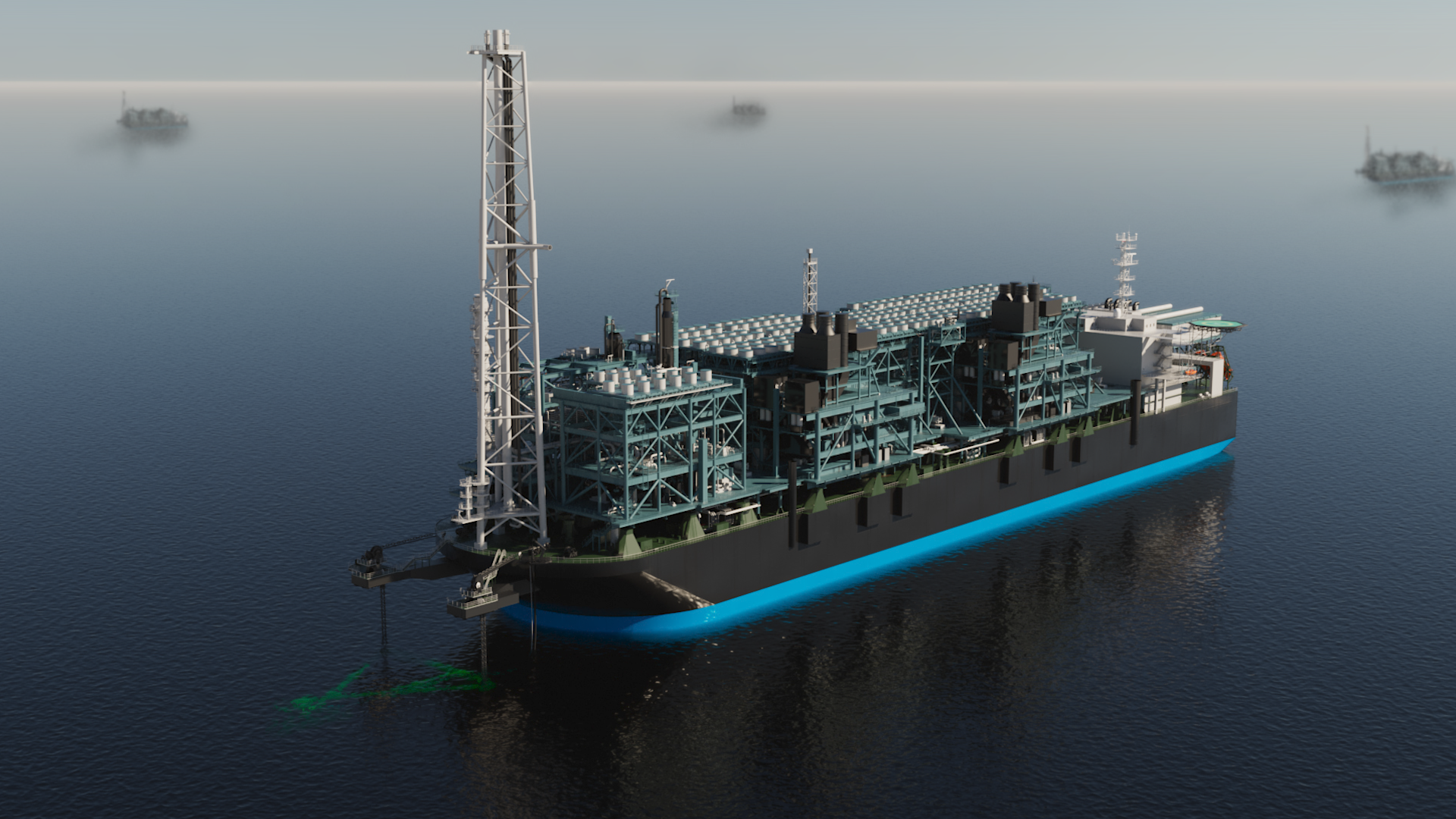

The Delfin Newbuild FLNG Vessel uses gas turbine driven technology and air-cooling for both liquefaction, process and utility cooling duties. The FLNG design is a liquefier concept that receives “pipeline quality feedgas” and is therefore not producing from a reservoir like an “LNG FPSO”. As such the design is significantly less complex and lower in costs. The Company has also developed with Black & Veatch and SHI an electric-drive FLNG solution that can be used in locations where renewable electric power is available to reduce emissions from the LNG facility. This e-FLNG was developed as a ‘derivative’ of the Delfin FLNG design, which demonstrate the generic versatility of a Liquefier FLNG.

In addition to the Newbuild FLNG solution, the company has a complete FLNG Vessel design based on a conversion concept. This conversion FLNG design is an alternative solution for the Delfin project.

Both the Newbuild and the Conversion FLNG Vessels are designed with the PRICO liquefaction technology and have nameplate capacities up to abt. 3.5 MTPA.

- The Delfin Deepwater Port comprises the subsea pipeline connection and mooring system for hook-up of the FLNGV

- The Delfin Deepwater Port will be licensed, constructed and operated under the Deep Water Port Act of 1974 (DWPA) under the jurisdiction of MARAD and the USCG

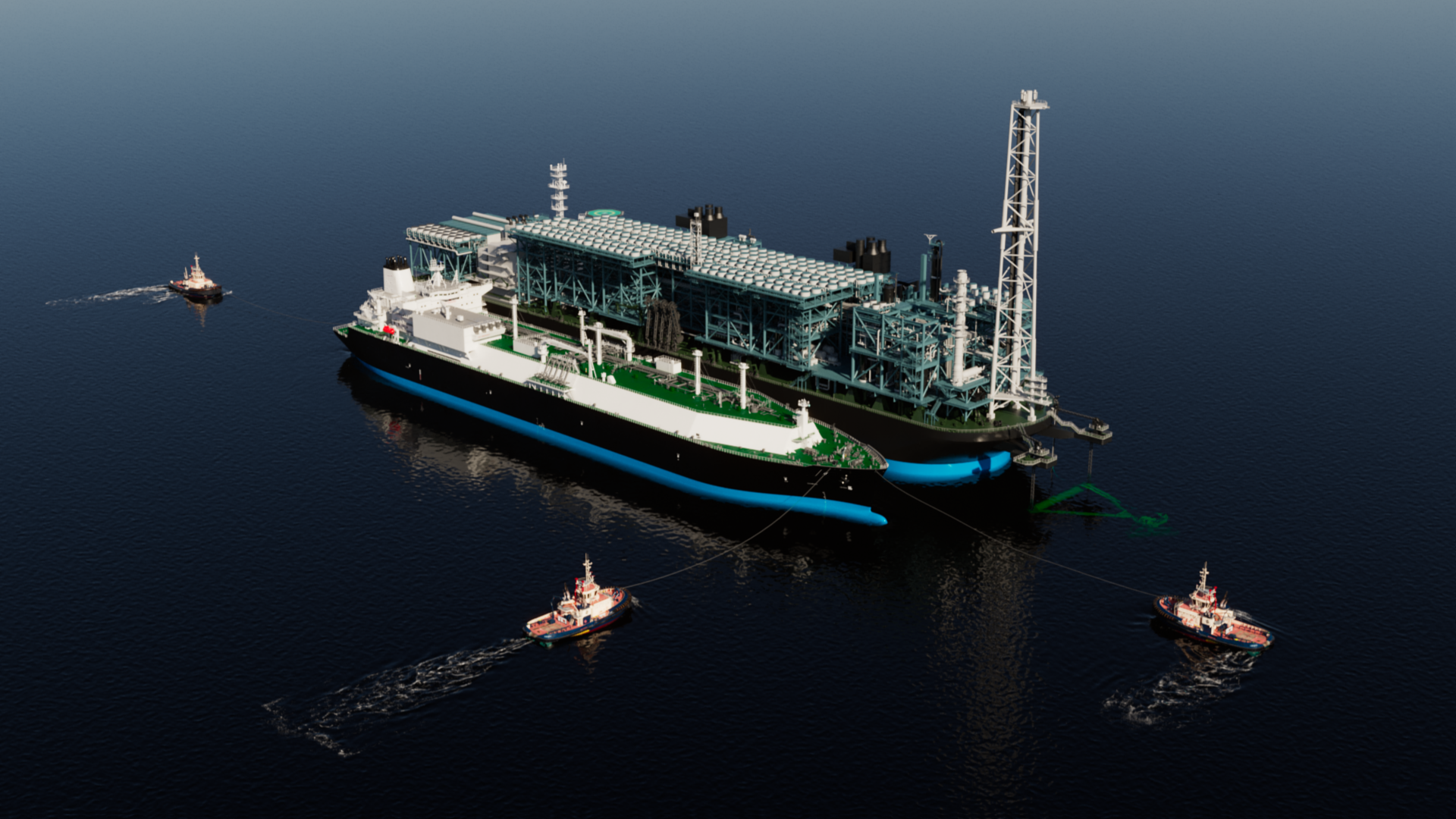

- The FLNG Vessel is an integrated berth for the visiting LNG carrier

- LNG carriers will be assisted by tugs and the FLNGV will have thrusters for heading control

- Mooring Masters will assist the LNGC captains to conduct the approach and berthing maneuvering

- Side-by-Side LNG loading operations is a well-established practice with several thousands performed between LNGC/FSRU and LNGC/FLNG

- Being offshore the LNG carriers can swiftly position and tender Notice-Of-Readiness before being escorted by dedicated tugs to berth along an FLNGV. Time and costs for pilotage and channel navigation congestion and delays is avoided and the collision risk is absolutely minimal

- The FLNG Vessel and its mooring system are designed for the worst (Winter) storms which may occur on the site

- Should a tropical storm or hurricane approach the site or otherwise be expected to have a severe impact on the site, the FLNGV will disconnect and sail away and bring the facility to a calm offshore location. Upon return the Vessel reconnects and start operations.

- Disconnectable mooring systems and operational procedures are similar to what has been successfully used in the FPSO industry for decades

Floating LNG technology has undergone a development, qualification and maturing phase over the past 15 years. The successful operation of the first units have demonstrated this technology is available as a reliable new monetization technology. Especially the Liquefier FLNG Vessels have proven to be robust in operation and can be constructed at low costs with attractive execution schedules.