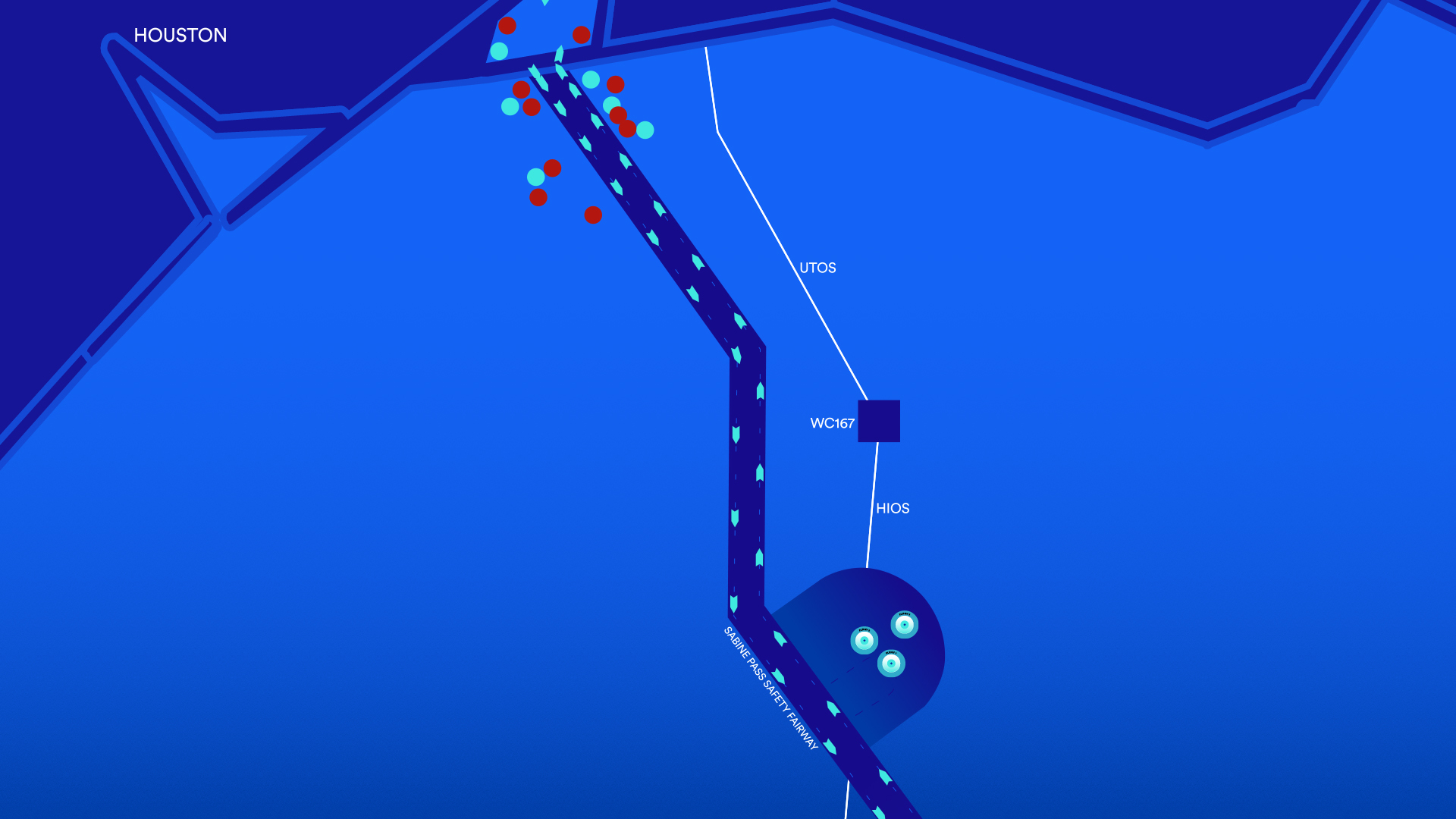

The Delfin LNG Project has unique characteristics that result in minimal environmental impacts and footprint, differentiating it from onshore LNG projects. Importantly, the Delfin LNG Deepwater Port will be some 40 nautical miles away from shore, and therefore any impact on “front-line communities” would be minimal. The Project will re-purpose existing pipelines and utilize liquefaction facilities on floating vessels, which are constructed at existing shipyards. This results in the efficient use of existing infrastructure and existing construction facilities, which further minimizes the environmental impacts. Furthermore, the project has developed the FLNG Vessels by applying Best Available Technology (BAT) in compliance with the Record Of Decision and the Deepwater Port Act to reduce emissions and effluents.

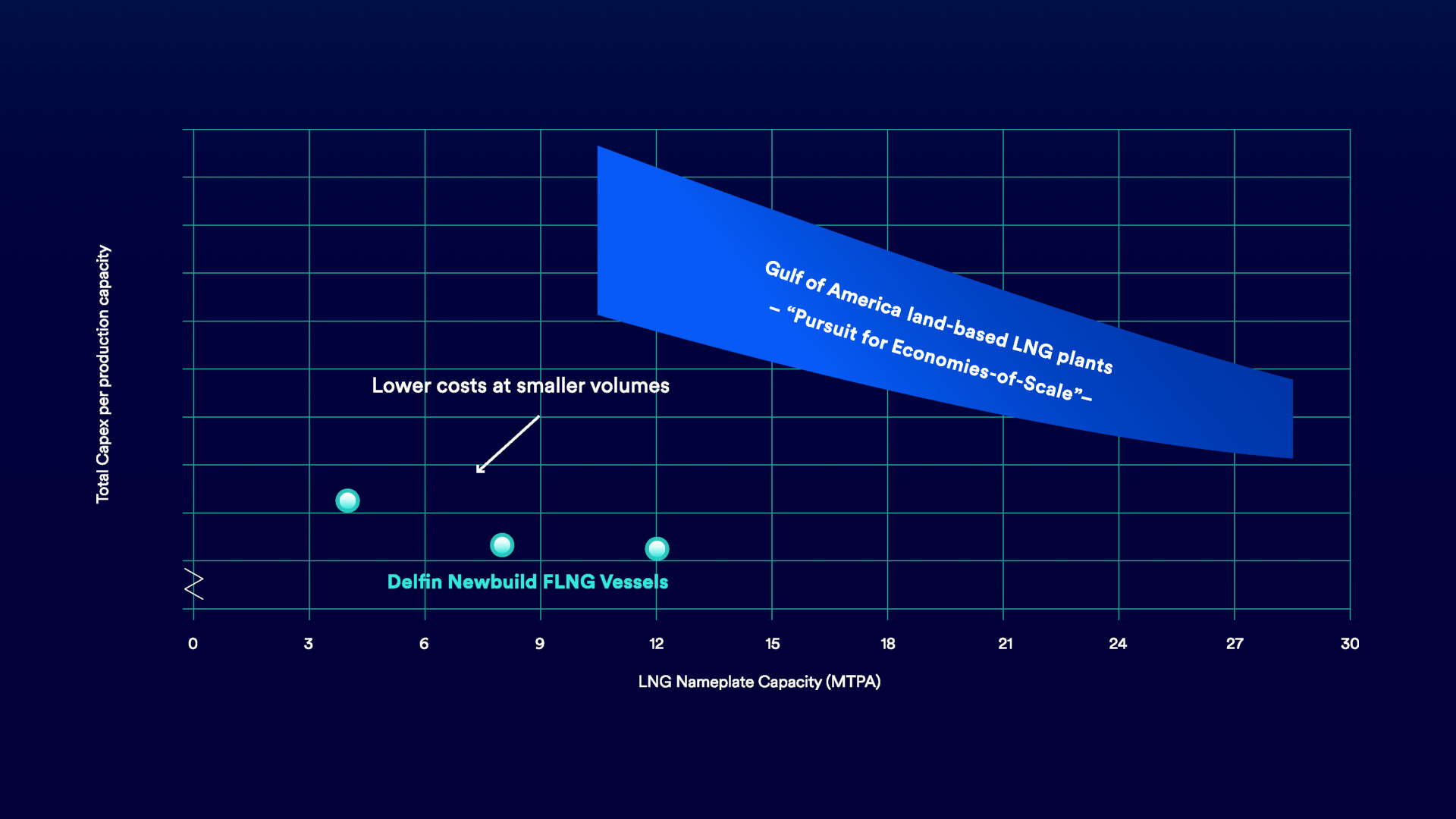

By using (existing) offshore pipelines, building the entire LNG plant at existing shipyards and with the LNG carrier berth integrated with the FLNG Vessel, these projects can reduce the capital costs significantly compared to onshore LNG plants.

Each FLNG Vessel is developed as a separate project with its own commercial and financial structure and its own FID. This results in a much lower FID threshold of abt. 3 MTPA for contracting its capacity compared to land-based terminals. This benefit together with lower capital costs allows the company to offer significant commercial flexibility to its clients and partners, whether this relates to commercial models, tenors, risk/upside sharing, equity participation or the joint development of the wider LNG value chain.

Being offshore, and FLNG project avoids traffic congestion at the port entrances and rivers along the US Gulf Coast. And with Delfin being the 100% owner of the “Deepwater Port” it is in control of all the marine operations at the Deepwater Port.

The FLNG Vessels are constructed in an existing shipyard using existing practices, methods and technologies resulting in a “manufacturing style of fabrication”, which reduces construction and schedule risk.